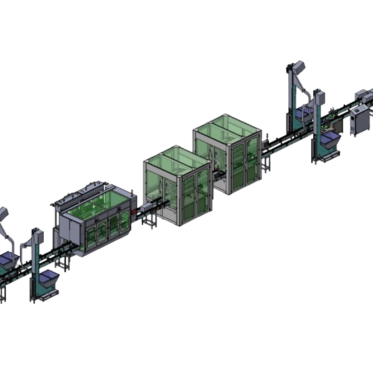

Automatic Packaging Machines

Automatic Cold Cream Filling Line :

USP POINTS FOR STANDARD LINE :

1. High-precision Servo-Based filling mechanism

2. Production capacity of up to 400 Bottles per minute for 15ml SKU with 48mm Mouth Diameter.

3. Low Maintenance cost

4. Compact design – occupies Minimal Floor Space

5. Dual-Track system for efficient workflow

6. High Filling Accuracy Of 0.5% for consistent product quality

7. Every 3 Secs. a total of 10 bottles gets sealed on each track.

Machine’s Features :

Product Profile :-

1. Jar Unscrambler

- Uses Waterfall Technology to align and sort jars.

- Automatically straightens jars and places them onto the conveyor.

- Equipped with a Rejection System to discard upside-down jars before filling.

2. Automatic Hopper Piston Filling Machine - Servo Based

- Dual filling system with 20 Heads for High-Speed Filling.

- 4 Servo Motors used — each motor Controls 5 Nozzles for precision.

- Includes “No Jar - No Fill” sensor system to avoid product wastage.

3. Automatic Reel - To - Reel Foil Conduction Sealing Machine

- Designed with High Hygiene and safety standards.

- Foil roll unwinding system Minimizes Material Wastage.

- Every 3 Seconds a total of 10 Jars gets sealed on each track.

4. Automatic Cap Pressing Machine with Unscrambler

- Roller-Based Capping mechanism that helps press caps firmly.

- Compact design to Occupy Minimal Floor Space.

- Adaptable design to fit multiple cap sizes.

5. Automatic Top & Bottom Labelling Machine

- Applies one label on the jar cap and one on the jar bottom simultaneously.

- Equipped with a High-Precision servo motor for Accurate label placement.

- High-speed Synchronized Labelling ensures clean, consistent results.

6. Automatic Jar Inverted, Laser Printing & Converter

- Inverter flips jars after labelling to enable bottom-side printing.

- Laser printer prints up to 4 lines of text on the bottom label.

- Converter reorients jars upright before sending them for shrink wrapping.

7. Automatic Shrink-Wrapping Machine

- Pneumatic diverter included for Traffic Management at high speed.

- Efficient handling of grouped jars for final-stage packaging.

- Provides tight and uniform shrink wrapping for a professional finish.

Cosmetic Cold Cream 50 Grams Jar Feeder Filling Foiling & Capping Line : https://youtu.be/jFDhy0_8C8E?si=G6rVpXJFWlgAVH1K