Molds for PET Packaging

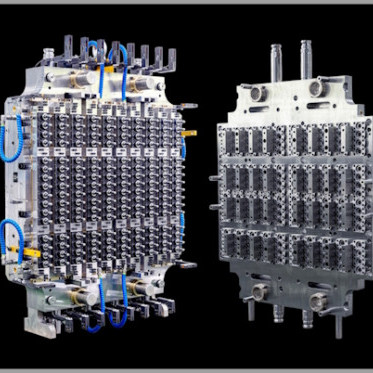

PET preform injection mold

• Specification: Cold half of 32, 48, 56, 72, 96, 144 and 160 cavities.

• Neck finishes: 26/22 (compatibility with tethered cap available), 1881, 1810, 1716, 29/25, 30/25, 38mm, etc.

• Applicable machines: various brands of preform injection molding systems.

• Preform molds for specialized applications available.

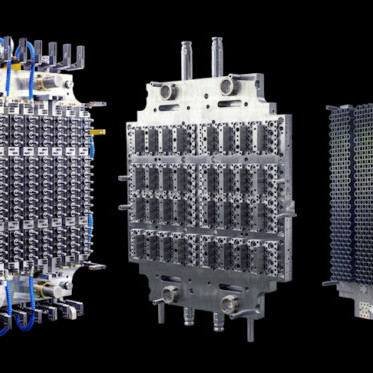

PET injection hot runner

• Specification: Up to 144 cavities for preform injection and 96 cavities for closure injection.

• Applicable machines: various brands of injection molding systems.

PET stretch blow mold

• PET containers for beverages including water, carbonated soft drinks (CSD), hot fill and aseptic bottles, etc.

• Containers for other industries such as food, edible oil, condiment, cosmetic, personal care, household and pharmaceutical, etc.

• Compatible with various brands of two-stage and single-stage blowing equipment.

Closure mold

• Specification: one-piece cap and two-piece cap.

• Neck finishes: 26/22, 1881, 1810, 1716, 29/25, 30/25, 38mm, etc.

• Applicable machines: various brands of injection molding and/or compression molding systems.

• Applicable to various industries including beverage (tethered closure option available), food, edible oil, cosmetic, pharmaceutical, etc.

Engineering conversions and solutions for normal and special packages

• Mold and production line conversion for containers modification. (Preform / bottle designs, neck finishes, light-weighting, etc.)

• Specialized packages applied with multilayer co-injection technology.

• Containers with integrally molded handles.

• Turn-key production solutions available.