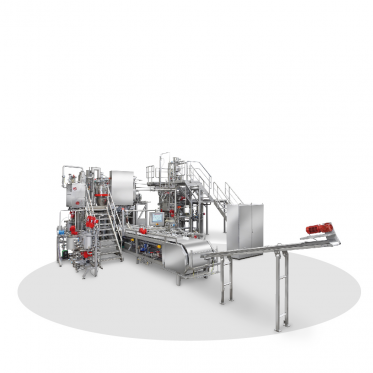

Sucroliner

With the SUCROLINER® 1731, we have succeeded for the first time in developing a fully integrated processing system that processes all the confectionery masses currently in demand on the market with a low residual water content. During the design, particular emphasis was placed on the following properties:

- hygienic design (EDHEC, GMP),

- high availability,

- easy maintenance and low availability losses due to maintenance intervals,

- Diagnosis for predictive maintenance,

- ready for Industry 4.0,

- quick installation of the system in your factory by mounting all mechanical and electrical components on a frame,

- central connection of all supply media (steam, water, electricity, compressed air),

- fully integrated CIP cleaning.

The output of the SUCROLINER® 1731 is up to 1800 kg/h and up to four different masses can be flavoured.

The integrated design means that standard slurry or slurry with little or no additional recipe water can be processed. This enables the operator to save steam energy. Another option is to design the 1731 as an NPA , which can be operated without compressed air. If protein-containing masses are to be processed, the system can be optionally expanded, while retaining the basic components.

Of course, the SUCROLINER® 1731 also has the tried-and-tested CROSSFLOW® cookers, which have been further developed in recent years and have now become almost the industry standard.